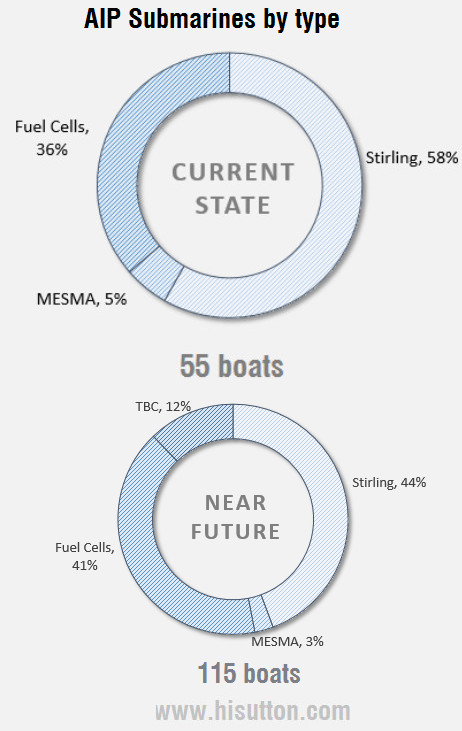

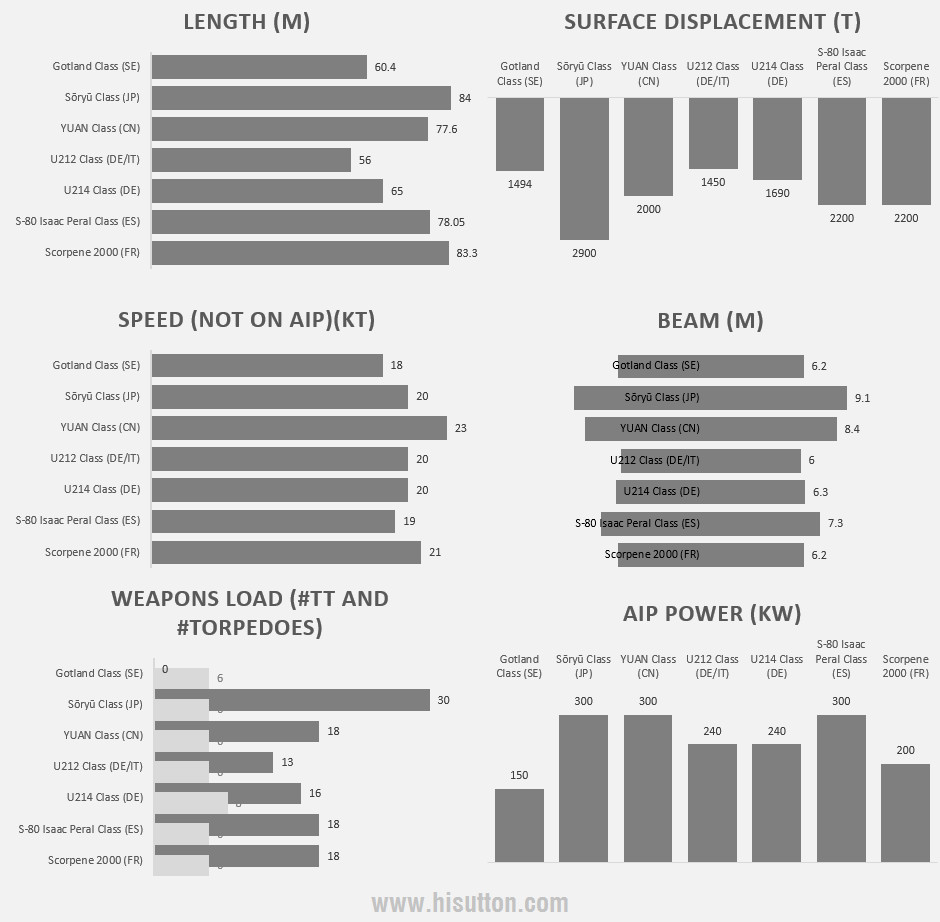

There are currently over 50 AIP submarines in service around the world, with the number likely to double in the coming decade. The largest single operator is China.

There are currently over 50 AIP submarines in service around the world, with the number likely to double in the coming decade. The largest single operator is China.

Air-Independent Power (AIP) allows a submarine to run its electric motor and other electrical systems without using the batteries. It reduces the frequency with which the submarine has to put its mast above the surface to suck in air for the diesel engines to recharge the batteries. The submarine still has to snort for brief periods on most days in order to ventilate, but is much less exposed than conventional diesel-electric submarines. During operations, if the tactical situation prohibits ventilation then the submarine can delay snorting for much longer than normal. And it can revert to lighting oxygen candles (or equivalent) in dire situations. Therefore the submarine can remain submerged for much longer, giving the submarine commander much greater flexibility.

Air-Independent Power (AIP) allows a submarine to run its electric motor and other electrical systems without using the batteries. It reduces the frequency with which the submarine has to put its mast above the surface to suck in air for the diesel engines to recharge the batteries. The submarine still has to snort for brief periods on most days in order to ventilate, but is much less exposed than conventional diesel-electric submarines. During operations, if the tactical situation prohibits ventilation then the submarine can delay snorting for much longer than normal. And it can revert to lighting oxygen candles (or equivalent) in dire situations. Therefore the submarine can remain submerged for much longer, giving the submarine commander much greater flexibility.

Another consideration is that most current AIP is only capable of providing power for very slow cruising – significantly less than 10kt. This is insufficient for wide-ocean transits and makes the submarine significantly slower than the task force. Therefore the regular diesel-electric power plant with snorkel cannot be done away with.

Get The essential guide to World Submarines

This Covert Shores Recognition Guide Covers over 80 classes of submarines including all types currently in service with World Navies.Check it out on Amazon

AIP is often described as Air-Independent Propulsion. This is no longer applicable as modern AIP Powers the electric motor rather than driving the propeller directly. Some historic and rare SDV systems are true Air-Independent Propulsion, but the term is outdated. As well as propelling the submarine, AIP provides lighting and electrical power for air-conditioning, refrigeration and other Hotel loads. Hence Air-Independent Power.

When operating at low power stages (i.e. low voltage), it is possible to run the AIP in parallel to the main batteries while using the batteries to power the propeller. This allows the batteries to be recharged in a similar mode to diesel-electric propulsion. However, it is inherently inefficient because there is a power loss involved in the transfer from the AIP to the batteries. The only use for this mode is when you need to give the batteries a top-up prior to a burst of high speed.

Initial systems were developed during World War Two but were not fielded operationally until the 1950s, and even then were mostly experimental. These early systems were often dangerous and got a bad reputation. As it transpired nuclear power held the key to unlimited endurance and first generation AIP fell from favor. It was only in the 1980s that the technology matured to the point that it could add days or even weeks to a submarine’s underwater endurance without being unacceptably dangerous or inefficient. There was never a huge appetite for AIP among the nuclear-sub equipped forces except from an export perspective (China may be the exception), but AIP promised a step-change in capability for conventional submarine forces. And AIP is not without its advantages over nuclear propulsion in some respects, particularly unit cost. AIP trades speed for stealth. On the down side it increases the size and displacement of the submarine, often involving an extra hull insert.

Today there are increasing numbers of AIP equipped submarines in service throughout the world, with more classes set to join several navies. Information on the topic is accessible but muddled with confusion between submarine types that are offered with AIP, and in-service units equipped with it. This article hopes to clarify some of these points.

Corrections and additions welcome.

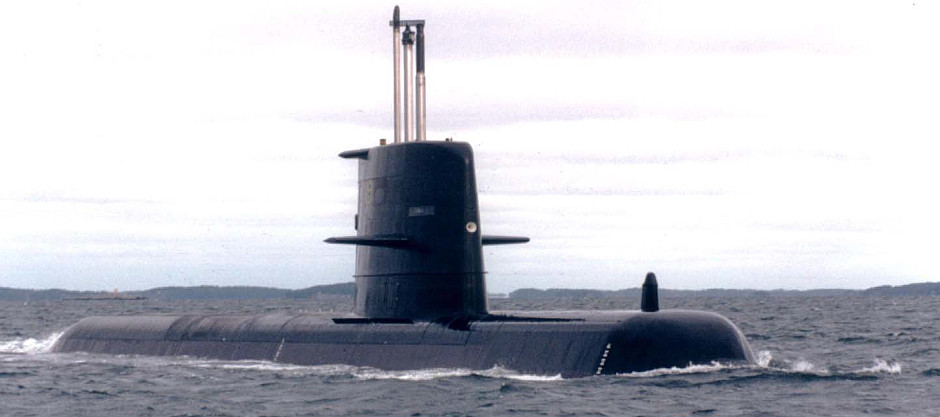

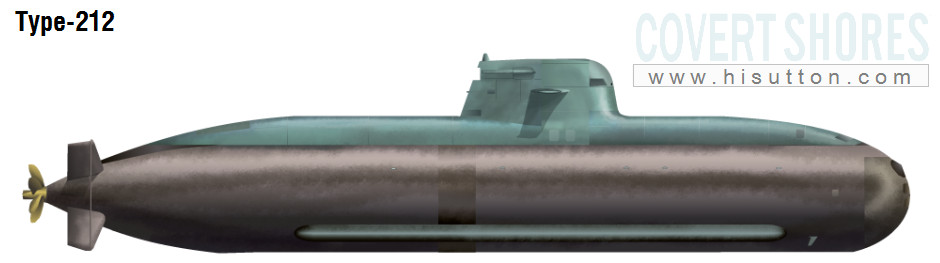

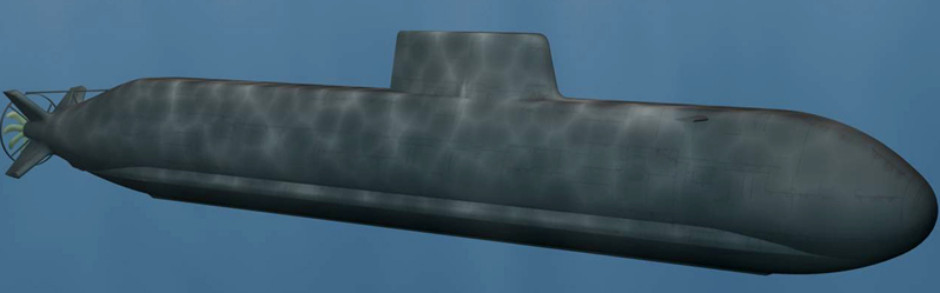

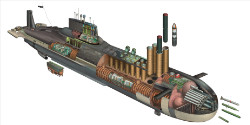

A German U212 Class AIP boat

THE book on Special Forces subs Covert Shores 2nd Edition. A world history of naval Special Forces, their missions and their specialist vehicles. SEALs, SBS, COMSUBIN, Sh-13, Spetsnaz, Kampfschwimmers, Commando Hubert, 4RR and many more.

Check it out on Amazon

History

By World War Two submarines were almost exclusively diesel powered with a secondary set of storage batteries to provide power and propulsion while the submarine was submerged. With the increasing air threat to submarines, an operational modus operandi developed whereby they submerged during the day and travelled on the surface at night. With their limited batteries and the need to retain an emergency reserve in the batteries in case they had to escape the enemy , this meant very little activity during the day. Two important improvements were fielded to remedy this weakness: a) snorkel masts to allow the boats diesel engines to be run without having to surface the submarine, and b) larger batteries. The use of diesels while submerged also allowed much faster transits during the day. These capabilities were exemplified by the Germany Type-XX1 U-boot, known as the “Elektroboote”.

But the snorkel still required the submarine to be very near the surface. So fully closed-cycle (i.e. no contact with surface air) propulsion systems were developed, particularly by the German firm Walter. This system involved storing Hydrogen Peroxide (also known as HTP meaning High Test Peroxide) and then decomposing it to give off oxygen which was fed to the diesel engine. The other method developed was simply to store liquid oxygen (or compressed air) to feed the engines. Due to the end of the War HTP was never fielded operationally.

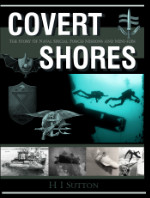

German Type XVII U-Boot with Walter type AIP

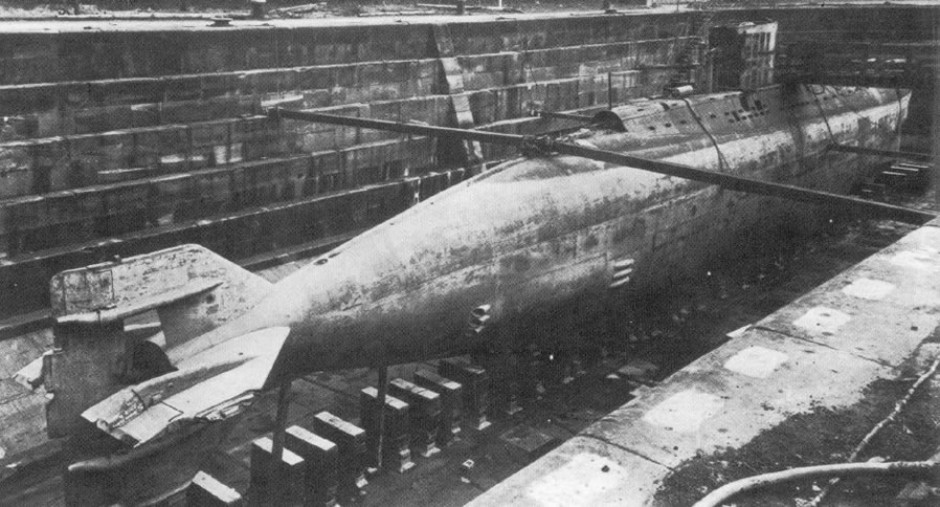

After the War both winning sides acquired advanced German submarine technology, including the Walter AIP. In the West the research into the Walter engine was led by the Royal Navy with the US Navy as an observer. A Walter equipped German Type XVIIB U-boat was pressed into service as HMS Meteorite. This was followed by two much larger trials boats, HMS Explorer and HMS Excalibur. The primary focus in British tests was to increase underwater performance rather than stealth. By allowing the powerful diesels to run underwater the boats were very fast, capable of 25kt. This may seem slow compared to later nuclear submarines but it was before the submarine world adopted the more hydrodynamic Albacore (tear-drop) hull form. The US Navy also built an HTP boat, putting the engine into the tiny X-Craft USS X-1. This midget submarine demonstrated the dangers of HTP when it exploded! Fortunately no one died and the boat was rebuilt with a conventional diesel. Much worse disasters occurred with HTP powered torpedoes, which caused the loss of the conventionally powered HMS Sidon in June 1955. An HTP fueled torpedo is also attributed with the more recent Kursk disaster. Safety concerns, combined with the advent of Nuclear propulsion led to the ditching of HTP as a submarine fuel.

1950s HTP submarines: British HMS Excalibur (left), American USS X-1 midget submarine (right)

At about the same time that Britain and America were experimenting with HTP submarines, the Soviet Union built a whole class of operational AIP boats. In the immediate postwar years Russia had built a single submarine (Project 617) with a German Walter hydrogen-peroxide system but this method was not pursued. Instead the Project 615 QUEBEC Class employed stored liquid oxygen (LOX) to run one of its three diesels in AIP mode. This system had actually been tested by the Soviet Navy in 1939 but development had stopped due to the War. The postwar QUEBEC class were small submarines of 460 tons and were armed with just four torpedo tubes without reloads. 30 boats were built but the class suffered issues with the stored oxygen and two boats were lost. Due to frequent mini-explosions in the engineering space the type was known as Zippos after the lighter. Although the USSR continued to build diesel-electric submarines after the advent of nuclear power, the QUEBEC Class was the only type with LOX AIP.

Project 615 QUEBEC Class AIP sub

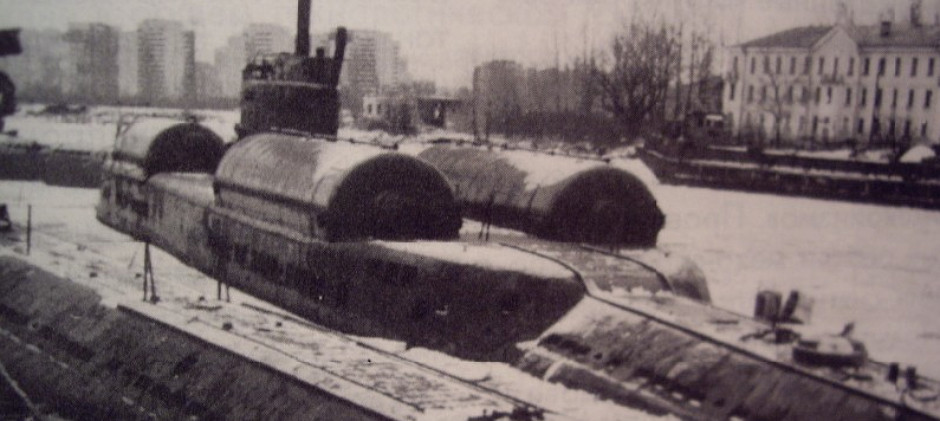

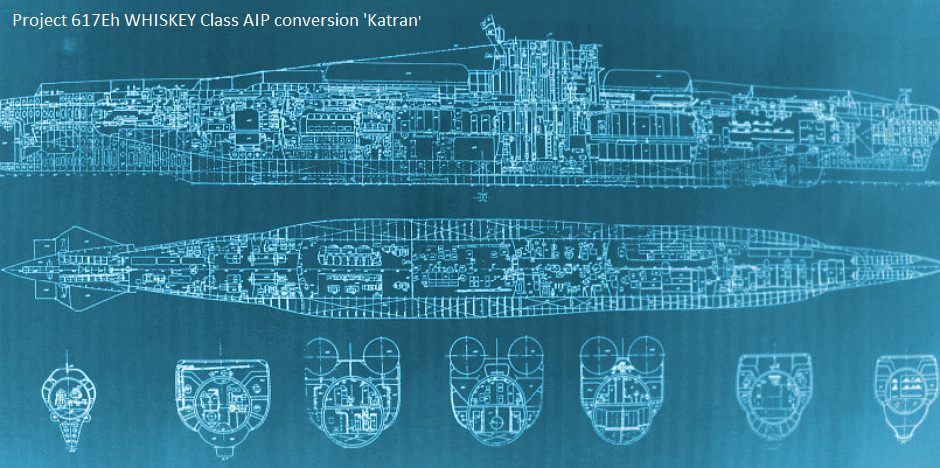

In the 1980s Russia again trailed AIP with a single vintage WHISKEY Class boat extensively modified with large cryogenic tanks attached to the outside of the hull containing hydrogen at -252oC and oxygen at -165oC. The fuel cell operated at very low temperatures but the reaction still produced heat and water, the latter being used for cooling. One of the boat’s diesels was replaced by an electrochemical plant and EhKhG280 generator, driving one of the boat’s two propellers. The system was deemed a success, extending the underwater endurance from 7 days at 2kt to 28 days at 2.5kt. Despite this the system was not put into production.

Project 613Eh WHISKEY Class AIP sub

During the latter Cold War several navies continued with the development of diesel-electric submarines and looked for a better and safer means of gaining AIP. Sweden in particular, who had a fleet of impressive coastal submarines optimized for the Baltic Sea, led the way. In the 1960s Sweden had seriously pursued nuclear propulsion but this program suffered politics and was too expensive, so the Swedish navy was wedded to diesel-electric submarines. The Swedish system developed in the 1980s was known as the Stirling generator. Soon other diesel-electric submarine building countries were playing catch-up with German Fuel Cell development starting in the mid 1980s.

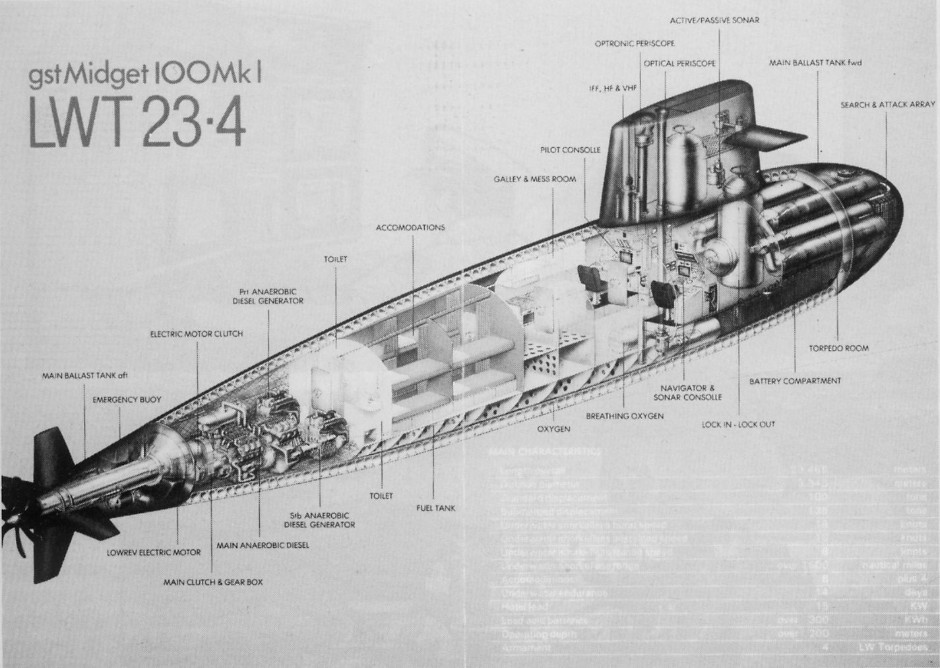

It should also be mentioned that Italian engineers experimented with AIP submarines in 1970s-80s. Their focus was more on midget submarines using oxygen stored within a unique tubular hull structure of the submarine. These Maritalia / GSE boats are a special topic in their own right.

Italian LWT 23-4 AIP submarine. Note the 'Pr1 Anaerobic Deisel Generator' label

Current AIP systems

Stirling Engines The original Stirling Engine was patented in 1816 by British engineer Robert Stirling as a rival to the Steam engine. Although successful it was largely replaced by the electric motor in the early 1900s and almost forgotten, until the Swedes looked for clever ways to propel a submarine. The engine’s heat is produced in a combustion chamber but it is separated from the actual engine. The heat is transferred to the engine's working gas (e.g. oxygen), operating in a completely closed system. The working gas forces the pistons in the engine to move, thus producing mechanical energy.

Stirling Engines The original Stirling Engine was patented in 1816 by British engineer Robert Stirling as a rival to the Steam engine. Although successful it was largely replaced by the electric motor in the early 1900s and almost forgotten, until the Swedes looked for clever ways to propel a submarine. The engine’s heat is produced in a combustion chamber but it is separated from the actual engine. The heat is transferred to the engine's working gas (e.g. oxygen), operating in a completely closed system. The working gas forces the pistons in the engine to move, thus producing mechanical energy.

Pros: Stirling engines are well tested and simple

Cons: They are relatively bulky, comparatively noisy due to moving parts. Limits the submarine’s operating depth to about 200m when in use.

Fuel Cells mix oxygen with a hydrogen-rich chemical to produce an electric current. Fuel cells use an electrochemical reaction in which oxygen and a hydrogen-rich fuel combine to form water, and electricity. Unlike internal combustion engines, the fuel is not combusted. Instead the energy is released electrocatalytically. Fuel Cell AIP was developed in the 1980s for the German Navy. The main system in use today is the German designed Seimens PEM (Polymer Electrolyte Module), but Indian and American firms also supply them for AIP submarines.

Fuel Cells mix oxygen with a hydrogen-rich chemical to produce an electric current. Fuel cells use an electrochemical reaction in which oxygen and a hydrogen-rich fuel combine to form water, and electricity. Unlike internal combustion engines, the fuel is not combusted. Instead the energy is released electrocatalytically. Fuel Cell AIP was developed in the 1980s for the German Navy. The main system in use today is the German designed Seimens PEM (Polymer Electrolyte Module), but Indian and American firms also supply them for AIP submarines.

Pros: Fuel Cells have a high power density and generally provide the longest endurance of current AIP systems. They are very quiet and the technology is seen as offering further potential

Cons: They are expensive and complex.

MESMA (Module d'Energie Sous-Marine Autonome) is a French system which runs a steam turbine off the chemical reaction between ethanol and oxygen. In many respects the system is based on the nuclear propulsion but with an alternative heat source. Only Pakistan fields this type of AIP currently.

MESMA (Module d'Energie Sous-Marine Autonome) is a French system which runs a steam turbine off the chemical reaction between ethanol and oxygen. In many respects the system is based on the nuclear propulsion but with an alternative heat source. Only Pakistan fields this type of AIP currently.

Pros: MESMA has a high power output potentially allowing greatest underwater speed

Cons: They are relatively thirsty, noisy and have complex plumbing.

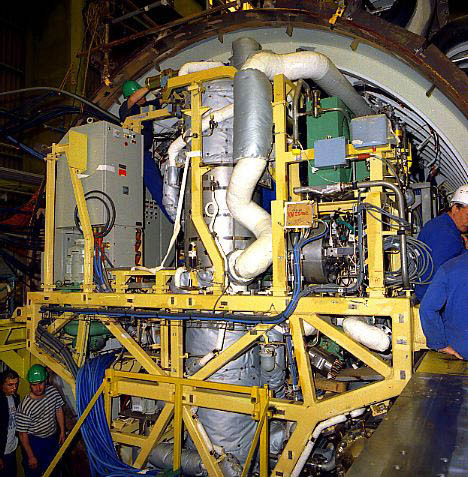

MESMA AIP.

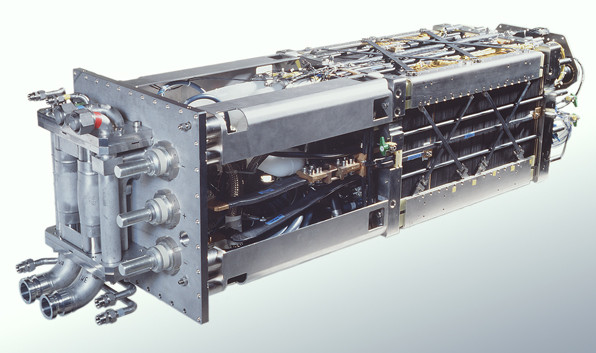

SINAVY PEM fuel Cell AIP.

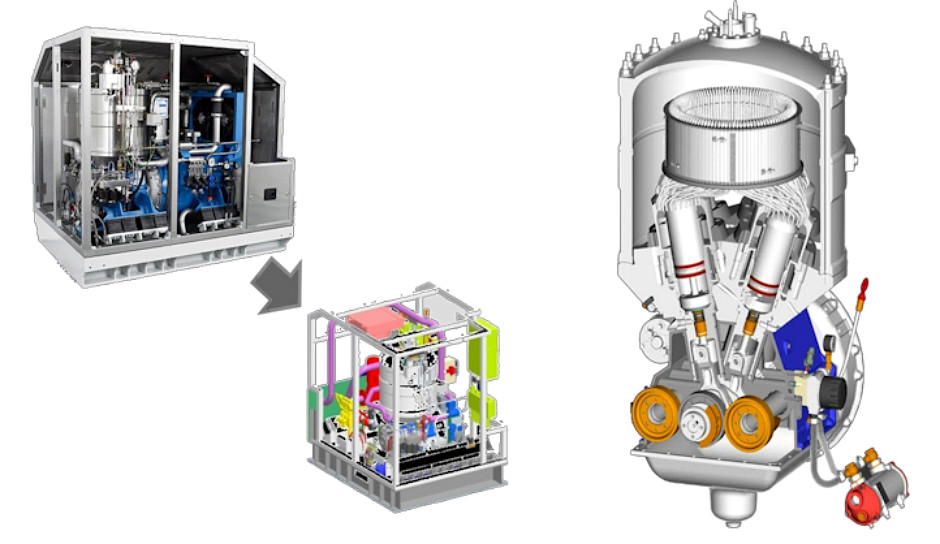

Stirling AIP. Source SAAB

Active AIP Classes

Gotland Class, Sweden

Gotland Class, Sweden

The first major submarine class designed from scratch as an AIP boat, the Gotland Class has a reputation from its impressive performance during a two year loan to the US Navy. Like most Swedish subs the boat is small and optimized for the Baltic Sea. Unusually it is armed with both 533mm (21”) heavyweight torpedoes and smaller 400mm (15.75”) anti-submarine torpedoes launched from dedicated tubes.

(

( ) Södermanland class, Sweden

) Södermanland class, Sweden

Built as conventional diesel-electric submarines, all four boats of this class were converted to AIP. Two remain with Sweden and two were transferred to Singapore where they are known as the Archer Class.

U212 Class, Germany/Italy

U212 Class, Germany/Italy

Italian Special Foces emerge from a Type-212 submarine. Credit Massimo Sestini

The Type-212 (aka U-212) is a German-Italian project for a submarine to replace the Type-206 and Sauro Class boats respectively. It was designed by Howaldtswerke-Deutsche Werft AG (HDW) with Italian firm Fincantieri SpA with the first delivery in 2002. The design incorporates a substantial section of double-hull construction aft of the sail which allows external carriage of the hydrogen and oxygen cylinders for the fuel-cell AIP. The upper casing and sail are completely faired-in and the entire boat is constructed of non-metallic materials. Given both navies proud and capable special forces histories (COMSUBIN in Italy and Kampfschwimmers in Germany), the type is designed to be well suited to special operations, including operating in extremely shallow water and carriage of an SDV on the back.

(

( ) U214 Class (Exported to Greece, Turkey, Portugal and South Korea)

) U214 Class (Exported to Greece, Turkey, Portugal and South Korea)

An export boat based partly on the smaller Type-212 (see above), the Type-214 (aka U-214) design has many of the same features. The sail is extensively faired-in, but the single-hull construction is noticeable relatively to the fatter Type-212. The diving planes are moved to the forward casing and the stern features a conventional ‘+’ configuration rather than ‘x’. The compressed gases for the AIP have to be carried inside the pressure hull.

The Portuguese boats are designated Type-209PN and are slightly different from the ‘full’ Type-214 fit.

(

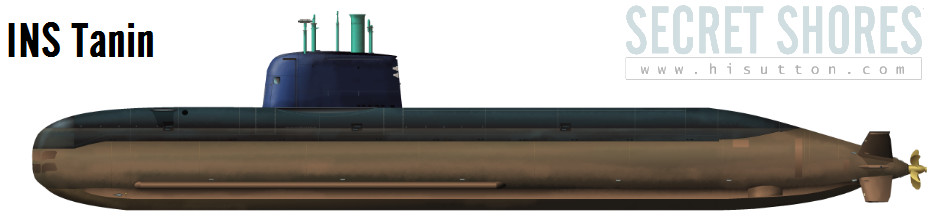

( ) Dolphin-II Class, Israel

) Dolphin-II Class, Israel

Based on the similar Dolphin Class boats already in service with the Israeli Navy, the Dolphin-II is stretched in order to accommodate the fuel cell AIP. These boats are highly capable, fitted with a range of Israeli systems. They are widely rumored to carry nuclear armed cruise missiles as part of Israel’s second-strike capability.

(

( ) Sōryū Class, Japan

) Sōryū Class, Japan

There is speculation that some later versions will replace the Stirling AIP with Li-Ion batteries. Li-iom batteries ae used in SDVs and DPVs but this will be the first application on such a large submarine. Although not AIP in the way that the term is commonly used, these new battery technologies will have a similar impact on underwater endurance and promise greater depth and quitter operation.

(

( ) Asashio, Japan

) Asashio, Japan

In the build up to the Sōryū Class submarine program, a single Harushio Class submarine, the Asashio, was modified to test the Swedish Stirling AIP. The boat is still in active service.

(

( ) Khalid Class, Pakistan

) Khalid Class, Pakistan

As originally ordered Pakistan’s three Agosta-90B were to be conventional diesel-electric boats. Third boat was delivered with the French MESMA AIP system and subsequently the other two were retrofitted, making the class the first AIP boats in the region.

Type-039A YUAN Class, China

Type-039A YUAN Class, China

Influenced by the Russian KILO Class submarine operated by China, the indigenous Type-039A YUAN Class incorporates a conventional tail, fairwater planes and a Stirling type AIP. This class is currently the most numerous type of AIP submarine.

Type-032 QING Class, China

Type-032 QING Class, China

A unique test submarine, the QING Class boat is thought to be the largest conventional submarine in the world. The massive sail incorporates vertical launch tubes for Submarine launched Ballistic Missiles (SLBMs), and the aft section includes a VLS for cruise missiles. Both capabilities are understood to be for testing only.

Future AIP Classes

(

( ) S-80 Isaac Peral Class, Spain

) S-80 Isaac Peral Class, Spain

Based on the French Scorpene design, the S-80 class took on a more Spanish flavor after disagreements with the DCNS. Four boats are on order to replace the same number of aging Agosta class SSKs with the first now expected to enter service in 2018.

Instead of the French MESMA system, the S-80’s AIP uses a bioethanol fuel cell system provided in part by an American firm.

Kalvari Class, India

Kalvari Class, India

Based on the French Scorpene design, 9 boats are planned for the Indian Navy. Of the 6 currently on order, only the last two are set to have AIP. Instead of using the French MESMA system, these AIP boats will use Phosphoric acid fuel cells designed by the Naval Materials Research Laboratory of Indian Defence Research and Development Organisation

A26 Class, Sweden

A26 Class, Sweden

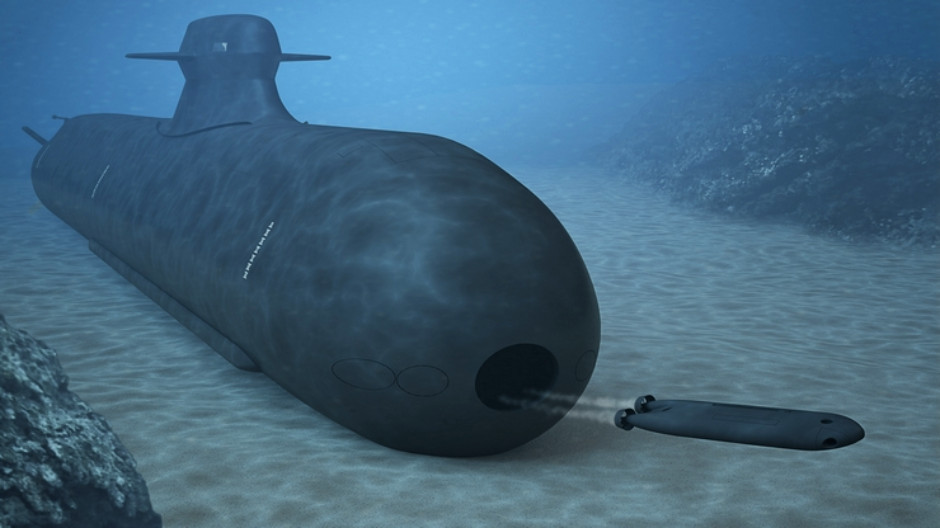

Intended to replace the Sodermanland Class, the A26 design has had a long and tortuous development. Sweden had sold the submarine builder Kockums to their German rivals TKMS which meant that they could not compete in many markets and is also blamed for the slow progress on the Swedish successor submarine program, the A26 (the politics of this are complex, worth researching to form your own view). Eventually Sweden conducted a defacto re-Swedification of Kockums with a wholesale move to Saab, who took on the a26 program. The sub is relatively small to suit Swedish needs and is noted for its special forces capability which features both a large lock-in/out hangar in the bow and potentially an SDV recess in the aft casing (likely for a SEAL Carrier).

Type-216 / 218SG Class, Germany

Type-216 / 218SG Class, Germany

Aimed at the Australian market, the Type-216 is a much enlarged follow-on from the Type-212 and Type-214 classes. The Singaporean order for two Type-218SG boats may refer to a closely related design, possibly with Stirling engine AIP rather than Fuel Cells for commonality with other Singaporean AIP boats.

SMX OCEAN design, France

SMX OCEAN design, France

French shipbuilder DCNS has been promoting the large SMX Ocean next generation SSK with MESMA AIP. The design is actually based on the Barracuda Class SSN but with AIP replacing the nuclear reactor. The design is notable for the extent to which Special Forces are catered for, a characteristic of recent French designs and in part inherited from the SSN base. No orders have been announced.

Vidar design, UK

Vidar design, UK

British design consultancy BMT has proposed a series of AIP submarine designs under the Vida brand. Refreshed every few years, the designs tend to be double-hulled with a stealthy faceted outer hull. No orders have been forthcoming.

Lada Class, Russia

Lada Class, Russia

Although frequently reported as an AIP submarine, none of the Lada Class are currently equipped and design of a Russian fuel cell AIP system is still ongoing. The Lada Class is an export orientated design based on the KILO Class but smaller and with single-hull construction.

Related articles (Full index of popular Covert Shores articles)

Barbel Class - the last front-line diesel boats int the US Navy

Barbel Class - the last front-line diesel boats int the US Navy

UOES3 (Button 5.60) dry SEAL Delivery Vehicle

UOES3 (Button 5.60) dry SEAL Delivery Vehicle

P.09851 KHABAROVSK and KANYON (Status-6)

P.09851 KHABAROVSK and KANYON (Status-6)

Russian Typhoon Class SSBN

Russian Typhoon Class SSBN

Russian Sarov experimental sub

Russian Sarov experimental sub

First DDS - Type-IIIA U-Boat

First DDS - Type-IIIA U-Boat

Iranian Fateh Class SSK

Iranian Fateh Class SSK

History of Israeli subs

History of Israeli subs

Maritalia GST-23+ Midget Submarine

Maritalia GST-23+ Midget Submarine

Project 09852 Belgorod Special Mission submarine (spy sub)

Project 09852 Belgorod Special Mission submarine (spy sub)